Additive manufacturing process

By Adina Moloman

By Adina Moloman

Sources: Forbes, The Economist

According to The Economist, additive manufacturing is becoming the third industrial revolution, where this new manufacturing process will help manufacturers to shorten supply chains, eliminate shipping costs and reduce lead times. This also are the advantages that Mexico Manufacturers are using for attracting foreign direct investment, especially from the United States.

Additive technology or 3D technology has been around for about 20 years and is in constant investigation and improvement.

To prototype a product in 3D it requires huge resources, but in the future it expected everyone to have a 3D printer in every home.

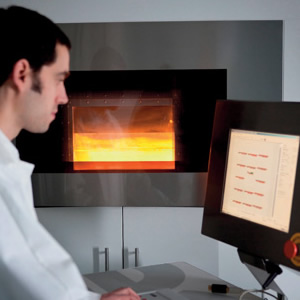

The system for making three-dimensional objects is based on an additive process, building objects up layer by layer. Every object is made up of millions of tiny layers. Also needed are highly complex designs with powerful computer software to turn them into real products.

This technology is all about printing things whatever might occur you.

A range of products created so far, including medical devices. Last year surgeons in the Netherlands printed a new titanium jaw for a patient. Also dental crowns and shells for hearing aids are already being printed; designers especially from US and Netherlands are already creating with 3D printers’ ready-to-wear shoes and dresses from plastic and nylon materials.

This year at The Society of Manufacturing Engineers (SME) RAPID 2012 Conference in Atlanta, buyers, sellers and end-users of design, prototyping, and tooling met and talked about direct manufacturing technologies trends and future opportunities in additive manufacturing (3D printing).

With this new and improved technology the approach to new product development is rethinking. The 3D printing process characterizes by printing items and objects as a complete part that requires no assembly. This is the production line of the future that probably might lead to changes to the Mexico Maquiladora Industry.