The Metal Fabrication Industry in Mexico

Mexico has progressed from a nation that offers cheap and unskilled labor using obsolete infrastructure to being one of the top ten modern industrial producers worldwide. Over the last several decades, the country has made great progress through its development of a high level of sophistication in manufacturing, product design processes, and process development. Additionally, Mexico now has a high degree of experience in technology and knowledge acquisition. Because of these circumstances, the metal fabrication industry in Mexico has made great strides forward.

By definition, the metalworking industry is dedicated to the use of the products obtained in the metallurgical processes for the manufacture of parts or finished products, such as machinery, equipment, or tools. These items are indispensable for the functioning of industrial production lines. The objective of the metalworking industry in Mexico is to transform raw materials into sheets, wires, plates, and other materials that are used in a variety of different manners in other well-developed Mexican industrial sectors.

Today, the industry in Mexico represents an essential part of the world economy’s productive capacity. Among other features, this is greatly due to its attractiveness to foreign investors, its geographical location, and its robust network of 11 free trade agreements that govern the conduct of duty-free commerce with 45 partner nations. Mexico currently supplies North America, and the rest of the world, with a wide range of high value-added manufactured products.

The metal fabricating industry in Mexico is one of the manufacturing economy’s pillars

The metal fabrication industry in Mexico is one of the most relevant value chains of any that is found in the country. It is, to a great extent, linked to Mexico’s capacity to manufacture products that require high levels of sophistication in its productive capacity. The metal fabrication industry has brought about an increase in the nation’s technological acumen and ability to innovate.

This sector represents a differentiator and a strength for the Mexican economy. The range of applications of the metalworking industry in Mexico is as broad as the opportunity offered today by the global market. This is particularly true in North America. Mexican fabricators are engaged in a wide range of processes from metal laminating and forming processes for storage racks, to manufacturing very complex parts in the aerospace or medical industry. Noteworthy is the case of the automotive industry. In this sector of Mexico’s manufacturing base, global companies are working on the transformation of metals in order to design lower weight parts without neglecting the resistance and safety that people expect in the vehicles that they purchase.

The metal fabrication industry in Mexico is important to other industries

The diversity of the productive sector of each economy is different from country to country. The development of the metal fabrication industry in Mexico has earned the nation an important place within the global economy. This is due to its continuous growth, and because of its significant investment in the automotive, aerospace, medical, electronics, and appliances industries. Additionally, in recent times, Mexico has become adept at the manufacture of molds, dies, and tooling.

The capacity of the latter sector has increased significantly due to the location of large automotive, aerospace, and other manufacturing industry clusters in Mexico. The continuous addition of these industries to Mexico’s expanding manufacturing base not only brings new operations and processes to the country but also promotes the widespread transfer of technology and knowledge. These developments have played a major role in making Mexico one of the 10 leading manufacturing countries in the world.

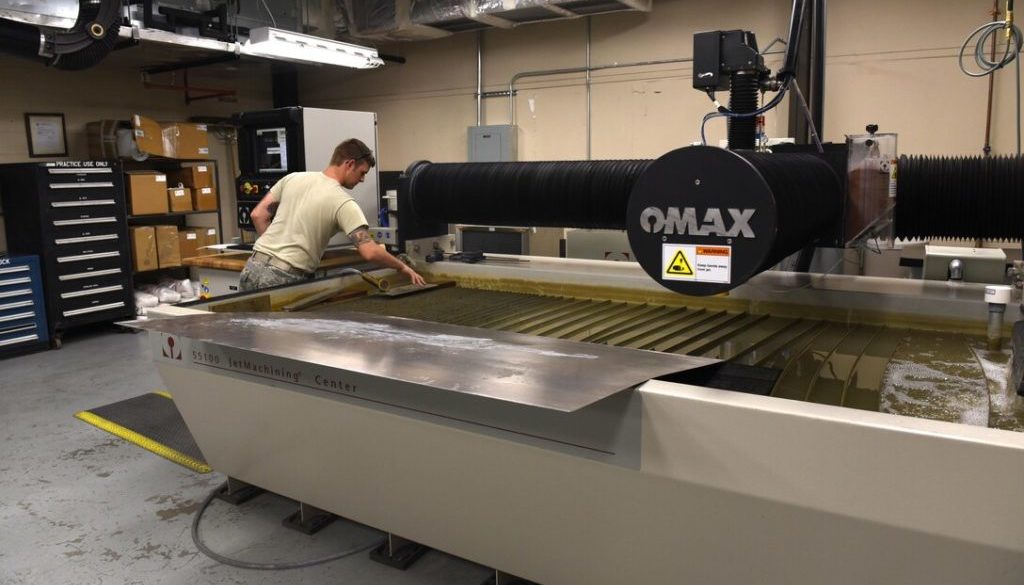

According to figures provided by the Tariff Information System Via the Internet (SIAVI), based on registered imports, the metal fabrication industry in Mexico receives just over 7,000 units of metalworking production equipment annually, which, in recent years, has increased this Mexican industrial sector’s levels of technology transfer, innovation, and sophistication in its manufacturing capabilities.

While in past decades manufacturing in Mexico solely represented a cheap labor alternative to high-cost countries, reusing and adapting outdated or old infrastructure from other countries, Mexico now boasts a production capacity and infrastructure that is comparable to that which can be found in other modern and industrialized nations.

The potential for the further development of the metal fabrication industry in Mexico is significant and the challenges are great. The evolution of the digital transformation of manufacturing called Industry 4.0 will undoubtedly have a measurable effect on the way each country copes with technological changes. Because of this emerging reality, Mexico must accelerate the pace of its investment in technology, and in the further installation of high value-added processes that can be utilized in the metal fabricating industry, as well as in other manufacturing sectors.